Cutting Vical S.A. acrylic sheet

The most common way of cutting acrylic sheet is using circular saws, similar to the ones used in carpentry. This types of saws offers a kind of facilities to make the cuts, low level of vibration, and enough power to make thick thickness and long length cutting. The rotation rate of this machine is from 2000 to 8000 rpm. The speed recommended to cut the acrylic is 3500 rpm and a power of 4 HP.

Conditions to select the machine:

» Be careful that the saw is well fitted to the disc height, this is essential to cut different thickness.

» The machine must have all the security conditions to the worker.

» There must be also a good system so that the acrylic sheet is well fixed to the table in order diminish vibration.

There are a wide range of saws in the market that can be used to cut acrylic, we recommend to use widia (tungsten carbide) because it last longer.

it is also important that the blade used, would be use only to cut acrylic, as it could be damaged if used with other materials.

The number of teeth depends on size of the saws, the rotation rate, and the thickness of the sheet.

| Sheet thickness (mm) | Disc diameter (mm) | Disc thickness (mm) | Number of teeth (mm) | Height of disc on the sheet (mm) |

| 2-4 | 200 | 1.5-2 | 96 | 3 |

| 5-10 | 250 | 2-3 | 82-96 | 6 |

| 12-15 | 300 | 3 | 82-96 | 12 |

| >18-22 | 300 | 3 | 48-52 | 12 |

| 25-50 | 300-350 | 3-3.5 | 48-52 | 12 |

The advance rate in the cutting process of the acrylic sheet will depend on the thickness of the sheet. But its advisable to use a rate of 2 meters/minute or 3 meters/minute.

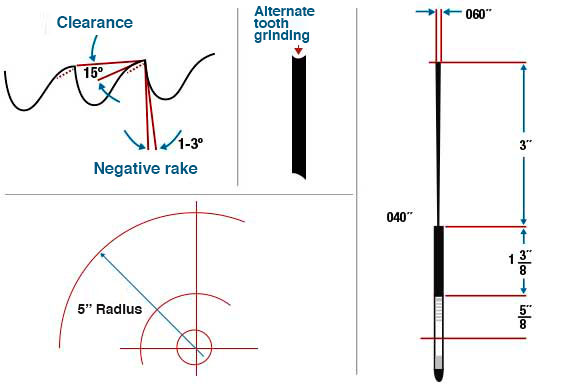

To cut acrylic the teeth of the saw must have certain shape and angle. The superior part of the teeth removes material in shape of chips, and the lateral angle let the chips out of the borders or edges.

Items to be considered to assemble the disc in the saw:

» Maximum oscillation in the center

» Be careful to verify that the disc has not hits or cracks

»T est that the working conditions are the right for the saw.

» The cutting edge of the teeth must strip the material from top to bottom

»The disc should be displaced upon the thickness of the sheet (see chart above)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Another method of cutting

Manual cutting: this is an inexpensive and fast procedure to cut sheet approximately 3 mm or less of width

Procedure:

» Put a ruler on the line you want to cut.

» Mark with a punch the line of cutting trying to mark with the most possible depth.

» Take out the ruler, put the sheet on the table so that the mark is along side with one border of the table.

» Hold firmly and give a sharp kick with the hand on the acrylic until it is broken.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .