Cementing of Vical S.A. acrylic sheet

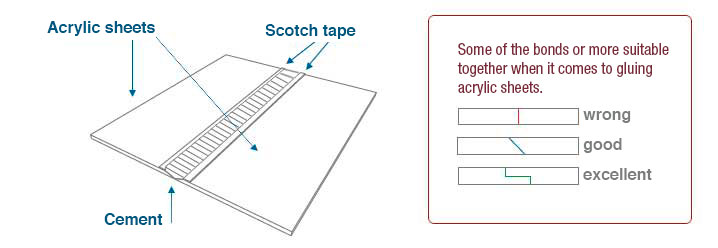

The acrylic sheets can be easily glued among them with some of the adhesives available in the market.

These adhesives must be used in well ventilated places and with a protection outfit, mask, gloves, etc.

If the parts to be glued do not fit exactly and there are free spaces, use glue with some viscosity.

Warning:

» The places where you work must be ventilated.

» DO NOT SMOKE the solvents are volatile and could be inflammable.

» Protect your skin from the contact with cement and solvents.

» DO NOT TRY TO GLUE the acrylic sheet when the temperature is below 12 C or above 35 C the ideal temperature is between 20 C and 25 C.

Preparation

First you have to prepare the area to be glued, the surface must be cleaned. If the surface is a bit rough sand with wet sanding paper fixed with a block of plain wood.

Do not polish the surface that will be glued because when you polish, convex surfaces and round edges are made and this weakness the joints.

If tension exist in the piece, cracks can be produced. To eliminate these tensions warm up the piece at 80 C.

For this kind of gluing use cements based on solvents.

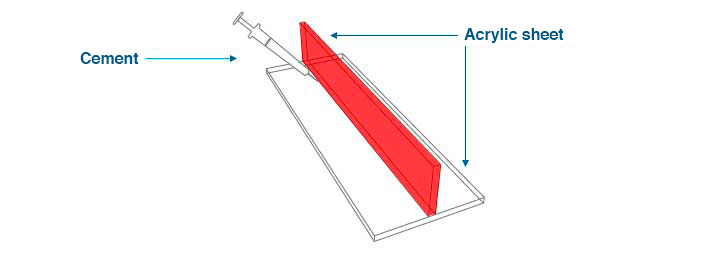

First you must be sure that the surfaces to be glued are properly adjusted. Then you have to join both sides with adhesive tape or with a press in such a way that the piece stays firmly held in its place. Then the glue has to be introduced with a syringe, being careful that this does not leak the solvent on the material.. You must wait for tree hours until the glue is dry.

The maximum hardness will reach in 24 hours.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gluing by immersion

Put cement in a recipient. Dip the edges of one of the pieces to be glued directly in the cement. Warning: Only the edge to be glued must be wet. The piece must be left in the cement:

for 20 seconds thin gouge

for 30 seconds thick gauge

This time can vary according to the solvent used and the hardness of the gluing that it is wanted to obtain.

Your experience will help you to get the best time for each circumstance. When the sheet is taken out of the cement keep for a few seconds to drain all the cement that can not absorbed. Carefully but quickly join the cut edge with the other part to be glued. Keep both parts together without pressing for 30 seconds. This allows the cement to act in the face where it was not applied. After then press slightly to remove possible bubbles. If you press a lot part of the cement could be expulsed. When the pieces are joined they will be placed in a press for approximately 30 minutes. Do not move the piece during this critic period.

The initial gluing lasts approximately 5 seconds the following process can take 3 hours. The joint will be strong after 24 hours of being done.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weathering

It has a weather resistance that cannot be reached by other plastic. The sheet resist the solar exposure, extreme cold, sudden change in temperature, salty water an others extreme conditions. The Vical SA sheets do not deteriorate with the passing of years. It is important to notice that the stability with respect to the environment is applied to the crystal acrylic sheet. The stability of the color acrylic sheet depend upon the colorant used.